| Sign In | Join Free | My gimpguru.org |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gimpguru.org |

|

Brand Name : Bievo

Model Number : DCGF14-12-5

Certification : CE, ISO 9001:2008

Place of Origin : China,Jiangsu

MOQ : 1set

Price : 15800dollers/set

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10 sets per month

Delivery Time : 30 working days

Packaging Details : wood case

Type : Filling machine

Name : Carbonated Drink Filling Line

Capacity : 5000BPH

Bottle type : PET Plastic Bottle

Filling Material : Beer, Water, soft drink

Bottle size : 200-2000ML

Key Selling Points : Long Service Life

Voltage : 380V/3 Phase

Washing pressure : 0.3-0.7Mpa

Size : 2300*1600*2500MM

Weight : 2600KG

Material : Stainless Steel SUS304 , SUS 316

Function : Bottle Washing Filling Capping

Marketing Type : New Product 2020

Condition : new

Filling type : Under Pressure Filling

Workshop Layout : Free Design

Driven Type : Electric

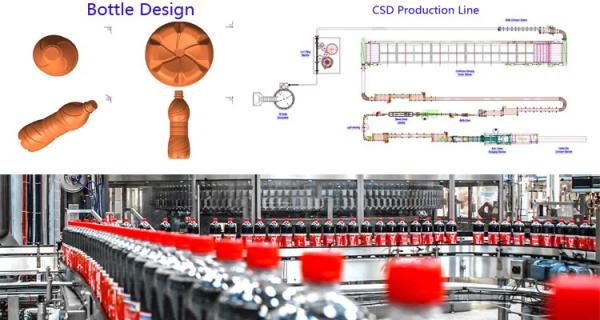

2000BPH Soft Drink Filling Machine Line For Carbonated Beverage Bottling Plant

Technical Parameters:

| Techinical parameter | |||

| Model | DCGF14/12/5 | DCGF16/16/5 | DCGF24/24/8 |

| Bottle specifications(mm) | Φ=50-100 H=160-340 | ||

| Capacity(350ml/bottle/hour) | 3000BPH | 5000BPH | 8000BPH |

| Filling temperature | 0-5 | ||

| Filling type | Press filling type | ||

| Motor power(kw) | 2.42 | 3.12 | 3.92 |

| Overall dimension(L*W*H)mm | 2360x1770x2700 | 2760x2060x2700 | 2800x2230x2700 |

| Weight(Kg) | 2800 | 3650 | 4800 |

Machines Details :

3 IN 1 Carbonated Soft Drinks Filling Machine

Out Look:

> 304 stainless steel frame

> Tempering Glass window, Clear & no odor

> Excellent start wheel design, easy change over parts

> Machine Base with anti-rust process, ensure the forever antirust

> All seal where liquid may Leakage & base neck come with rubber, water proof

> Manual lubrication system

Washing Part:

1)Into bottle way is flat conveyor cooperated with bottle feeding screw.

2)All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

| Electrical Brand List | |

| AC Contactor | SIEMENS (GERMANY) |

| Thermal overload relay | SIEMENS (GERMANY) |

| PLC | SIEMENS (GERMANY) |

| Touch Screen | SIEMENS (GERMANY) |

| Converter | SIEMENS (GERMANY) |

| Power Switch | SIEMENS (GERMANY) |

| Intermediate Relay | SCHNEIDER (FRANCE) |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a national level development zone - Zhangjiagang Economic And Technology Development Zone, covering area more than 8,000 square meters.We enjoy convenient transportation with Shanghai Hongqiao International Airport and Shanghai Pudong International Airport on hand.Which accumulated a great number of China's top technologists in the liquid beverage industry.We have complete system from designing, manufacturing, installation, training to after service.Our main product water production line, carbonated beverage production line . Fruit juice and milk production line ,3 to 5 gallons production line, daily chemical production line and so on.Plat and tube UHT device, CIP system.All the products are sold well.We devote ourselves to the development, research and production of liquid food and beverage filling and packing industry .

![]()

1. A: Are you factory?How many workers do you have?

B: Yes,we are factory. our factory is located in zhangjiagang near from shanghai. We have about 50 workers in our factory. 2. A: What about after sale service? B: 12months of electrical part and 18months of mechanical part after machine installed and running normally.

3. A: What about installation?

B: Our engineer can be sent to your country. but customer should pay the air tickets and 100usd as salary per person per day. besides, customer should arrange the accommodation for them during the trip.

4. A: What do we do if we encounter problem about the machine ?

B: Show us the picture or video of the problem. If the problem is from small machine, we will send you solution by video. If the problem is from large machine, our engineer will go to your factory (customer will pay the fee during the trip).

5. A: How can you control the quality and delivery?

B: All our machines will be tested before packaging. wooden packaing is strong and safety for long delivery .

1. Installation & debugging

After equipments reached the workshop of customer, place the equipments according to plane layout we offered. We will arrange seasoned technician for equipments installation, debugging and testing production at the same time to make the equipments reach the rated producing capacity of the line.

|

|

2000bph 3 Phase 0.7Mpa Automatic Soft Drink Filling Machine Images |